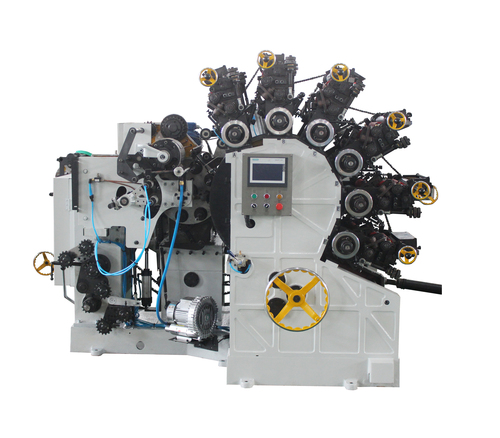

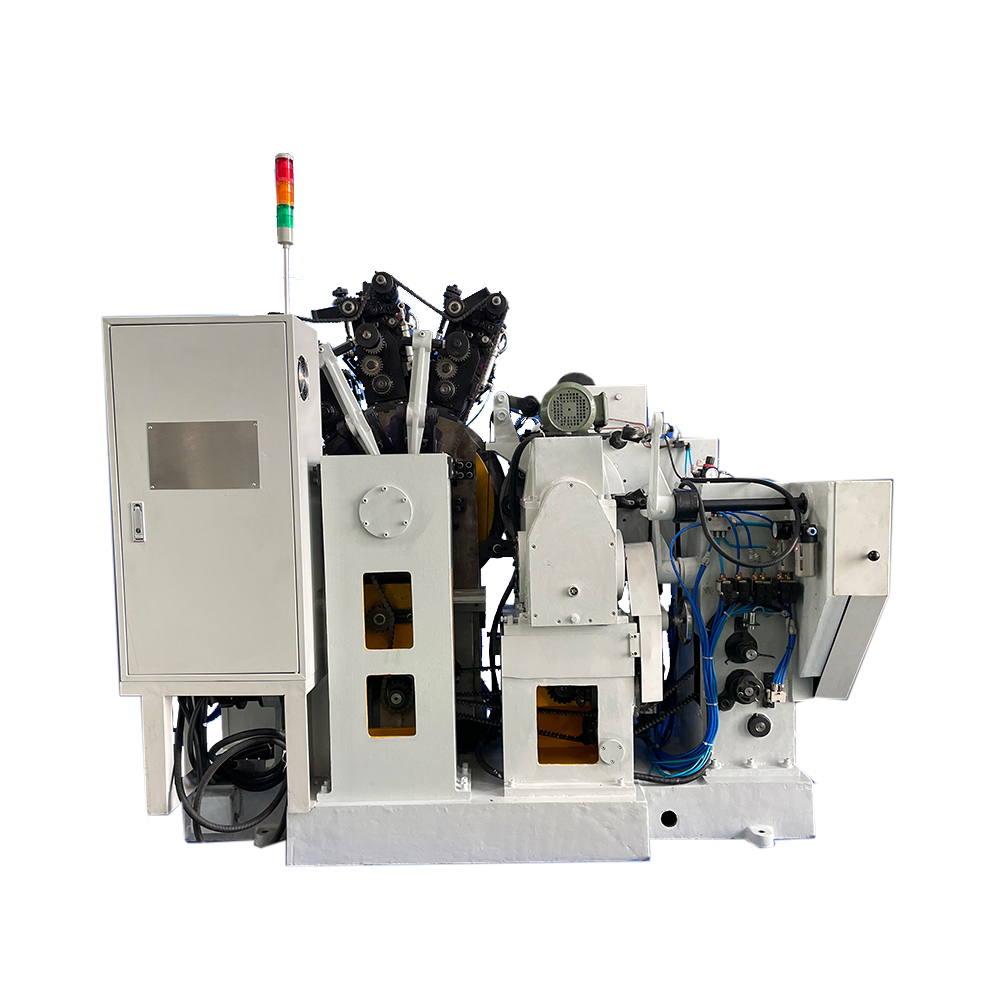

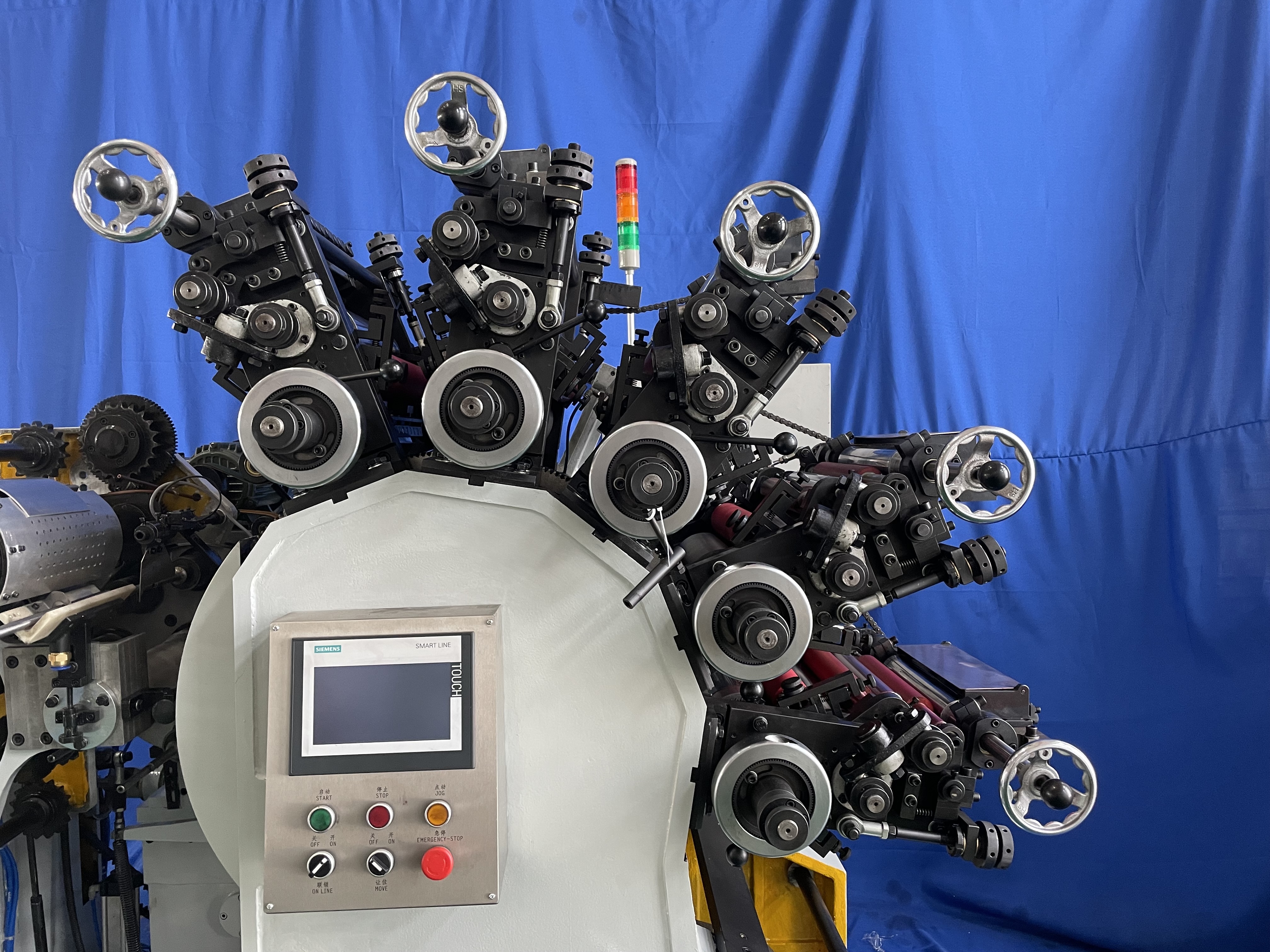

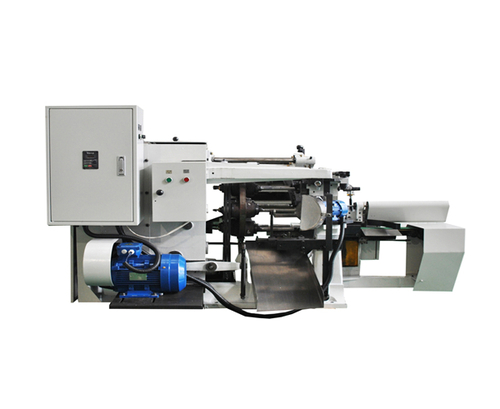

offset printing machine of aluminum glue tubes making equipment

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 3150 Watt (w)

- Pressure 0.6~0.8 mpa

- Dimension (L*W*H) 2230*1600*1800 Millimeter (mm)

- Click to View more

offset printing machine of aluminum glue tubes making equipment Price And Quantity

- 39500 USD ($)/Set

- 1 Set

offset printing machine of aluminum glue tubes making equipment Product Specifications

- Automatic

- New

- Other

- 0.6~0.8 mpa

- 3150 Watt (w)

- 1 year

- 3900 Kilograms (kg)

- 2230*1600*1800 Millimeter (mm)

- White

- Other

- Electricity

- 60 Pcs/min

offset printing machine of aluminum glue tubes making equipment Trade Information

- Shanghai

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 45 Set Per Year

- 3 Months

- Yes

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Asia, North America, Middle East

- All India

- CE

Product Description

We have 2 companies, both were founded by Mr. Tiger Jing Hu.

Wuxi Yingrun Machinery Technology Co.,Ltd. - Trading company

Wuxi Xinrun Packaging Machinery Technology Co., Ltd. - Manufacturer/Factory

Our main products are

‘Aluminum collapsible tubes production lines

‘Aluminum aerosol cans production lines

‘Electromagnetic shell production lines

Including Extrusion press machine, trimming machine, printing machine, capping machine, packing machine... ...

In addition, we also provide machine accessories (like spray guns, grippers,chains...), raw materials (aluminum slugs....) and so on.

If you have any needs, welcome to contact us.

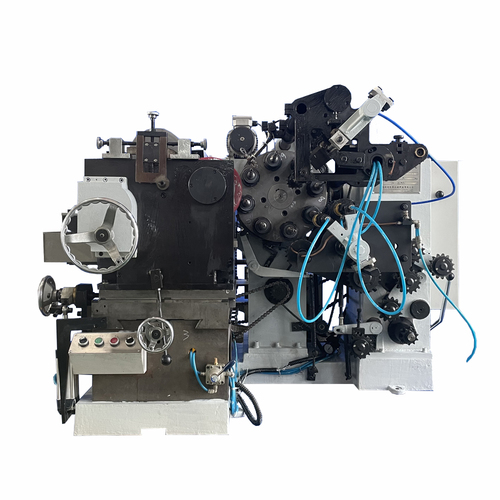

Printing machine is suitable for printing the surface of aluminum lead-tin, zinc and other metal tubes. It can realize polychrome printing of patterns in four colors.

The equipment can automatically insert the tubes from the pin of the conveyor chain that need to be printed on the mandrel for printing, and can automatically send the printed tubes to the pin of the conveyor chain for drying.

If no tube on the mandrel, the equipment can yield automatically through the proximity switch and the cylinder switch to avoid the mandrel being printed with ink.

This equipment converts the continuously running conveyor chain into intermittent movement through the eccentric movement of an eccentric wheel. When the conveyor chain pauses for a short time, the gripper will unplug the printed tube from the mandrel and insert the conveyor chain pin so that the tubes can enter the oven.