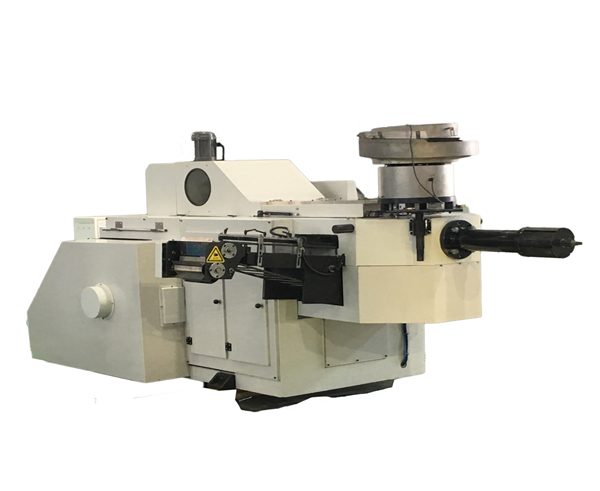

Extrusion Press Machine for aluminum tube production line

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 380 Volt (v)

- Pressure 0.6-0.8 mpa

- Surface Treatment Other

- Click to View more

Extrusion Press Machine for aluminum tube production line Price And Quantity

- 75000 USD ($)/Set

- 1 Set

Extrusion Press Machine for aluminum tube production line Product Specifications

- Electricity

- Other

- 2730*1315*1550 Millimeter (mm)

- Automatic

- Other

- 5200 Kilograms (kg)

- Industrial

- 0.6-0.8 mpa

- 90 Pcs/min

- 1year

- Other

- 380 Volt (v)

- white

Extrusion Press Machine for aluminum tube production line Trade Information

- Shanghai

- 50 Set Per Year

- 50 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Asia North America Middle East

- All India

- CE

Product Description

LJD series high speed horizontal cold extrusion machine, also known as high speed horizontal punch, is a new generation of high speed aluminum tube/can extrusion equipment developed and designed by our company. It is a special production equipment for extruding aluminum slug into embryo tube or other shape cylinder. Principle: the slug bowl automatically arranges and regularly sends the aluminum slugs into the blanking guide rail, and accurately sends the aluminum slugs into the press mould by the feeding gripper. Under the action of the crank link swing rod and the slider, the gap between the tip of punch and the mould hole controls the thickness of the tube. Through the annular gap between the carbide ring and the tip of punch, the round sheet is cold extruded once to form a blank tube and automatically stripper The chain outputs the billet in an orderly manner. The equipment can also set different extrusion process according to customer requirements.